Batteries represent one of the biggest, new manufacturing challenges of the 21st century. While it is true that global battery production is already in the tens of billions of units annually, the traditional battery technologies cannot meet the performance and cost targets for a rapidly growing range of battery applications. Most of us are already familiar with automotive battery applications in hybrid, plug-in hybrid, and all-electric vehicles.

In addition to the automotive industry there are exceptionally attractive applications for affordable, high-performance batteries in the electric power and alternative energy businesses. Wide implementation of residential battery storage can provide load-leveled electric power demand, as well as emergency back-up power. This distributed energy storage solution can also improve the efficiency of base power production and offset some of the need to invest in major grid infrastructure improvements. And, electric energy storage is essential to capture the full benefits of unsteady, alternative energy sources, such as solar and wind power. Here too the availability of affordable, high-performance battery technologies will help reduce the costs of grid expansion.

By now, the qualifying words “high-performance and affordable” should be clearly established caveats in this exciting vision of batteries as heroes for our energy challenges. Despite the intensive development efforts to date, the newly emerging battery technologies are infants compared to their very mature, older siblings in flashlights, cameras, and computers. For the emerging battery applications the energy storage and lifetime requirements are higher, the weight and cost targets are lower, and the manufacturing challenges are still being defined. Many of the promising new battery solutions only exist as notional designs in a CAD world, a world that is increasingly unfamiliar with the capabilities and constraints of available manufacturing technologies. In other words, the design guys and the manufacturing guys need to do a lot more communicating! We’ll try to help here.

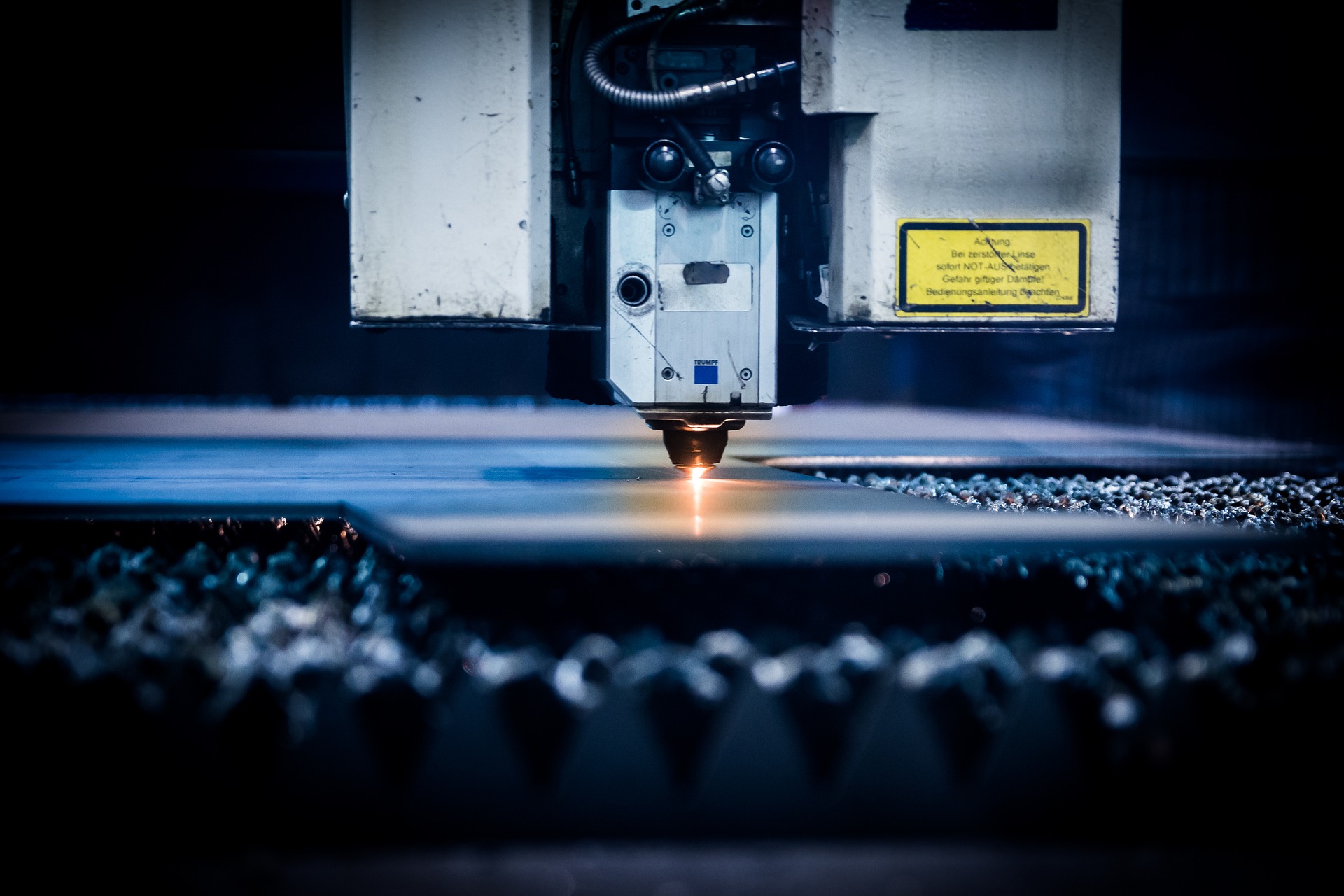

There is no declared or obvious winner among the numerous battery technologies that are in pursuit of the applications noted above. Lithium-ion, nickel-metal-hydride, zinc-air, sodium-sulfur, and many other battery chemistries are competing to satisfy the range of needs in the various application areas. And, within a given battery chemistry, there are many geometric variations that lead in turn to different possible manufacturing methods. The new batteries come in cylindrical or planar designs. The battery cells are stacked, packed, and otherwise arrayed to combine individual cells in parallel and series electrical circuits. The cell-to-cell connections may involve similar metals or different metals, in two or more layers. But despite the design diversity, there’s one common denominator that keeps showing up in nearly all of these battery concepts. That common challenge is the need to join thinner and thinner metals of various types at higher and higher speeds. This is laser territory.

Batteries nearly always include multiple metals, such as zinc, steel, aluminum, copper, titanium, nickel, etc. These metals may be electrodes, conductors, or simply containers. They may be uncoated or coated with another metal or a brew of battery elements. But, no matter what they are, they need to be as thin as possible for weight and cost minimization. Material thicknesses for many of the emerging battery designs range from 25 to 250 microns. The two primary requirements for joining these metals include creation of conduction paths and/or containment of electrolytes, but complete performance specifications for battery welds are unique to each battery design and application. Conductivity, strength, hermeticity, fatigue, and corrosion resistance are typical weld quality evaluation criteria. Then, after all these criteria are defined and met, the pivotal deciding factor is affordability.

Weld joint designs in batteries are crucial to manufacturing success. Edge (fillet) and butt welds are often tempting for the designer, but lap welds are by far the most likely to succeed. Lap welds offer much needed freedom from the precision joint-to-beam alignment required by the other two joint types. Lap welding also offers the ability to join many layers of battery elements for terminal consolidation tasks which may involve one or more material types. For instance, a stack of metals of one type may require welding to a “buss” conductor of another type. The possible joint configurations here are numerous and rapidly evolving.

Series electrical connections and buss connections usually require joining of dissimilar metals. It is in this area that laser welding, specifically high-speed (100 to 1000 mm/s) laser welding, offers benefits that cannot be achieved with other joining techniques. The availability of high-brightness fiber lasers facilitates high-speed welding, which results in low heat input and high solidification rates in the laser weld nugget. These high cooling rates suppress solidification defects that would ordinarily occur in mixed metal welding. One of the most notorious, crack prone, weld metal combinations is copper to aluminum, which also happens to be one of the most wanted metal combinations in lithium-ion batteries. High-speed fiber laser welding has been shown to achieve crack-free welding in this important metal combination. Other wanted and/or unusual metal combinations can also be laser welded when solidification rates are high. Finally, as enabling as these weld metal combinations may be, it is critical that their performance capabilities (especially strength, ductility, fatigue, and corrosion resistance) be evaluated for the intended battery application.